Osmo UV-Protection Oil Tints

All exterior woods grey into a patina color over time, but Osmo UV-Protection Oil Tints has been developed to maintain the wood's natural color and slow the greying process by (UV factor) 12 times in comparison to untreated wood.

It is a transparent, lightly pigmented and satin, natural oil based wood finish for exterior use. Microporous surface allows the wood to breathe and reduces swelling and shrinkage. Osmo UV-Protection Oil Tints is also furnished with active ingredients to protect the coating against mold, algae and fungal attack.

Ideal for windows, doors, cladding, fencing and other vertically structured joinery (not recommended on flat surfaces such as decking).

Protected perfectly against the sun – transparent, lightly pigmented UV protection for outdoor areas!

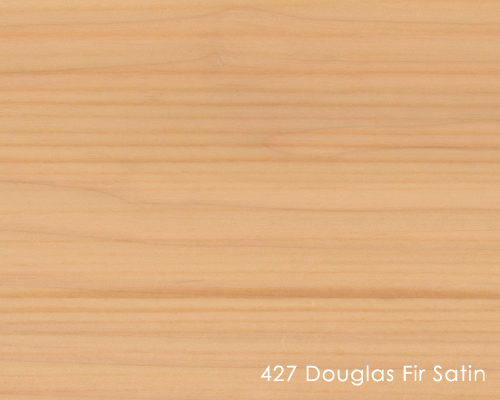

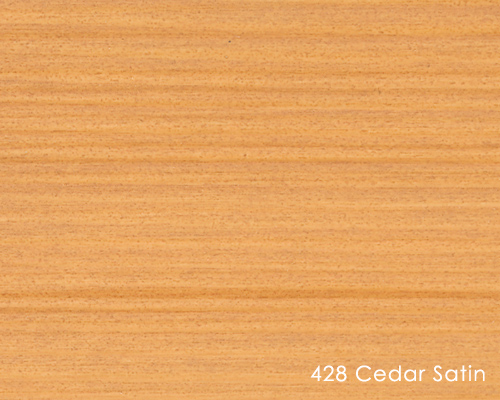

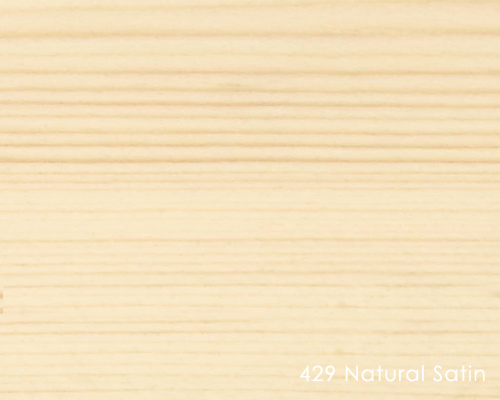

| Colors & Sheens | |

| Advantages |

|

| Can Sizes | 0.125L | 0.75L | 2.50L | 25.00L |

| Information |

|

| Documentation | |

| Application Tools |

|

Osmo UV-Protection Oil Tints is ideal for the protection of all vertical exterior wooden surfaces like Cladding | Garden Furniture | Doors | Windows | Shutters | Fencing | Wooden Houses | Carports | Pergolas plus lots more...

How to Apply UV-Protection Oil Tints

Finished surface in 2 days, 2 coats

Stir Well

Apply thinly

Let it Dry

Second Coat

Let it Dry

Tips:

- Recommended application: 55 ml/m² per coat.

- Wet coating can be corrected up to 15 min.

- Wood surface must be clean, dry and frost-free (moisture content max. 20%).

- Thoroughly clean or lightly sand old microporous stains or completely remove old varnishes before application.

- For areas exposed to strong weathering, such as weatherboard, post caps or window sills, please expect significantly shorter renovation intervals.

- Vertical elements mounted onto horizontal wood should have at least a 15 degree angle. Sharp edges must be rounded (radius > 2 mm).

- If the greying process has already begun, clean the surface with Osmo Wood Reviver Power Gel and refinish with 2 coats of Osmo UV-Protection-Oil Tints.

- To achieve the UV protection, it is necessary to apply 2 coats of UV-Protection-Oil Tints. With only one coat on untreated wood, the life of the coating is significantly shorter.

- For new resinous wood species (such as Cedar, Iroko, Teak, Mahogany etc.), please allow approx. three months exposure to the outside elements prior to application.

- Osmo UV-Protection Oil Tints Natural 429 protects wood nearly invisibly. The natural wood tone is preserved - it does not enhance the the natural color tone of the wood (no permanent wet effect). On dark/reddish wood species, Osmo UV-Protection Oil Tints Natural is visible as slightly white chalky surface. A trial application is always recommended.

- Oak contains a high acid content within its natural tannin and as a result causes the timber to blacken during exposure to cold and moist environments - especially during the winter periods. More frequent care and maintenance is required, particularly in its first couple of years of exposure to the elements, to maintain its decorative appearance.

Samples with UV-Protection Oil Tints