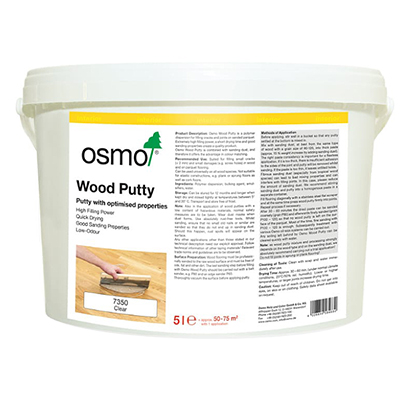

Osmo Wood Putty

Clear polymer dispersion for filling cracks and joints in sanded parquet. Extremely high filling strength, short drying times and good sanding properties create a quality product. Osmo Wood Putty is combined with sanding dust, and thus it offers a big advantage in that it matches the color of subsurface exactly.

Filling Small Joints with Optimized Properties!

| Colors & Sheens |

|

| Advantages |

|

| Can Sizes | 1.00L | 5.00L |

| Information |

|

| Documentation | Info Sheet Safety Sheet Declaration |

| Application Tools |

|

Osmo Wood Putty is suitable for filling small cracks (< 2 mm) and small damages (e.g. screw holes) in Wooden Flooring and Parquet. Can be used universally on all wood species.

How to Apply Osmo Wood Putty

Stir Well

Add Fine Sanding Dust

– P120 approx. 15% Weight –

Mix Well

Fill the Gaps

Let it Dry

– Normal Climatic Conditions –

Sand (P100/120)

Remove Dust

Apply Osmo Oil

– Clear/Transparent/Opaque Osmo Oil –

Tips:

- As wood putty mixture and processing strongly depends on the wood type and on the sanding dust, we absolutely recommend carrying out a trial application! Do not fill joints in sprung or solid plank flooring!

- Mix in sanding dust, at best from the same type of wood with a grain size of 80 – 120, into thick paste (approx. 15% weight increase by adding sanding dust). If too thick, adhesion to wood will be insufficient and putty may be removed when sanded. If too thin, holes will be left unfilled.

- After 30–60 minutes the dried paste can be sanded coarsely (grain P80) and afterwards finely sanded (grain P100–120) so that no wood putty is left on the surface of the parquet. Most of the time, fine sanding with P100–120 is enough.

- Do not add sanding dust with remnants of old coating to Wood Putty. Only use clean sanding dust for this purpose.

- Fibrous sanding dust, especially from exotic wood species, can lead to bad mixing properties and may prevent joints from being filled. In such cases, reduce the amount of sanding dust.

- Any Osmo Wood Putty deposits can be removed quickly with a wet cloth.